Design for manufacturing

In the world of audio equipment, design is often limited to the front of the device. This is different with the high-end audio tube amplifiers FOND designed for the Swiss manufacturer Zeiler Audio. Here, all elements from the controls to the smallest functional details inside the enclosure have also been formally defined. In addition to typical Swiss design maxims such as objectivity and formal timelessness, we consequently designed for manufacturing to achieve an aesthetic and consistent design.

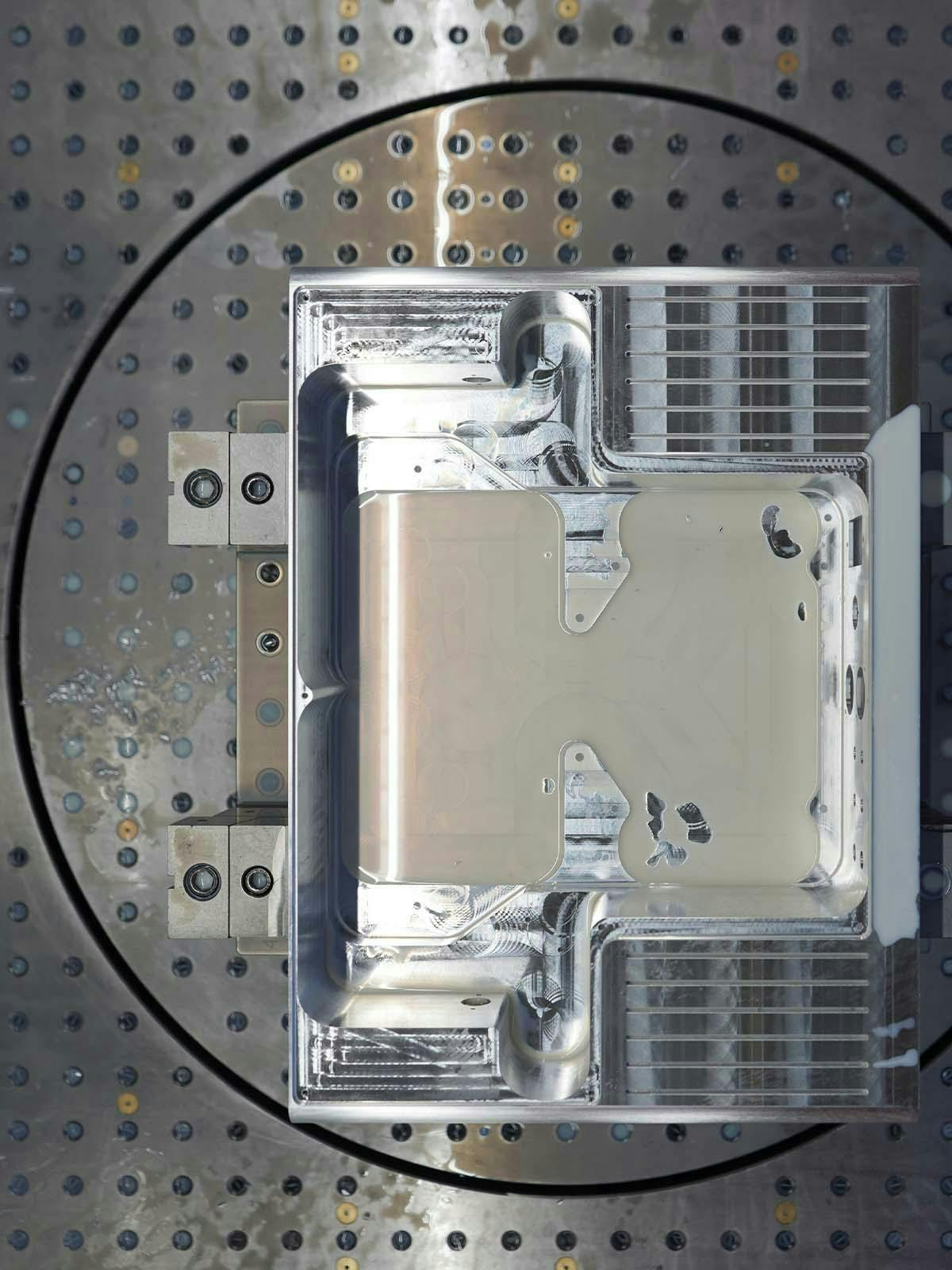

Aesthetics for milling

The technical specifications of CNC milling technology were translated into a formal vocabulary. This design based on milled geometries not only guarantees optimal manufacturability, but also leads to a very honest and consistent result in terms of formal aesthetics. The CNC machining takes place at a specialized company in the canton of Lucerne. There, solid aluminum blocks are reduced to about 80% with a 5-axis CNC milling machine. What remains is a high-precision full-metal housing that has a number of unique features. It has a high-end feel with finely detailed forms that appear to be cast from a single mold. The lightweight metal enables cooling of the electronic components and tubes through efficient heat dissipation. The optimal positioning and mounting of all electronic components results in the shortest possible wiring paths. By avoiding and reducing disturbing resonances as well as providing electromagnetic shielding, the enclosure contributes to the exceptional sound quality of Zeiler Audio equipment.

Sensuality via industrial anodizing

Milling is followed by surface treatment by a company specializing in electrolytic processes based in the Swiss Mittelland. The aluminum used is made of a special alloy to guarantee the best possible finish during the surface treatment. First, the enclosures are blasted by hand with glass beads to hide all milling marks and obtain a uniformly compacted surface. Then anodic oxidation gives the parts their typical matte black coloration and unique velvety feel. This complex procedure is also used for the coating of high-end camera housings and sports watches. All surfaces are coated with a hard anodized ceramic layer. It provides excellent wear and corrosion protection as well as very good electrical insulation and dielectric strength. A laser engraving exposes the aluminum for the filigree inscription on the back, which contrasts with the matte anodized background.

Manufacturable by design

Our goal is to achieve a perfect balance between sensual feel and timeless look to support Ralf Zeiler's claim of superior sound quality. The manufacturing partners also play a decisive role in this. Maintaining a good and particularly local network of professional suppliers and manufacturers is essential for a design studio with a holistic approach.

In order to successfully design such premium products, it is essential to know the manufacturing and assembly requirements and to negotiate directly with the manufacturers. This does not mean, however, that designers must completely submit to the fabrication conditions. Manufacturers are relatively conservative due to their own circumstances, as this allows them to guarantee efficiency and quality. In order to design truly innovative products, as a designer you have to convince not only the client, but always the producing partners as well. After all, they bear the responsibility if something doesn't work out during manufacturing. Close collaboration based on mutual trust and understanding of each other's competencies enables unique and manufacturable design solutions.

The assembly, wiring and soldering of all audio components up to the testing and measuring of every single device is done by hand in in Ralf Zeiler's workshop. To allow for the most efficient assembly, all mounting points are set to be as accessible as possible. The demands of elaborate point-to-point hand soldering informed our design process. The goal was to provide very short, accessible cable connections that give an aesthetically pleasing and premium overall appearance when fully soldered.

The result are high-end audio amplifiers that the renowned magazine Image Hifi describes as "acoustic and optical perfection in every respect". We are very proud that these mostly hidden but nevertheless important aspects of a consequent manufacturing friendly design are recognized and appreciated by the specialized press (read the Image Hifi article here). Because good design is always contextual design - be it in manufacturing or in use.

How to design for manufacturing?

Client

ZEILER Audio

Designers