Designing a startup's 3D printing platform

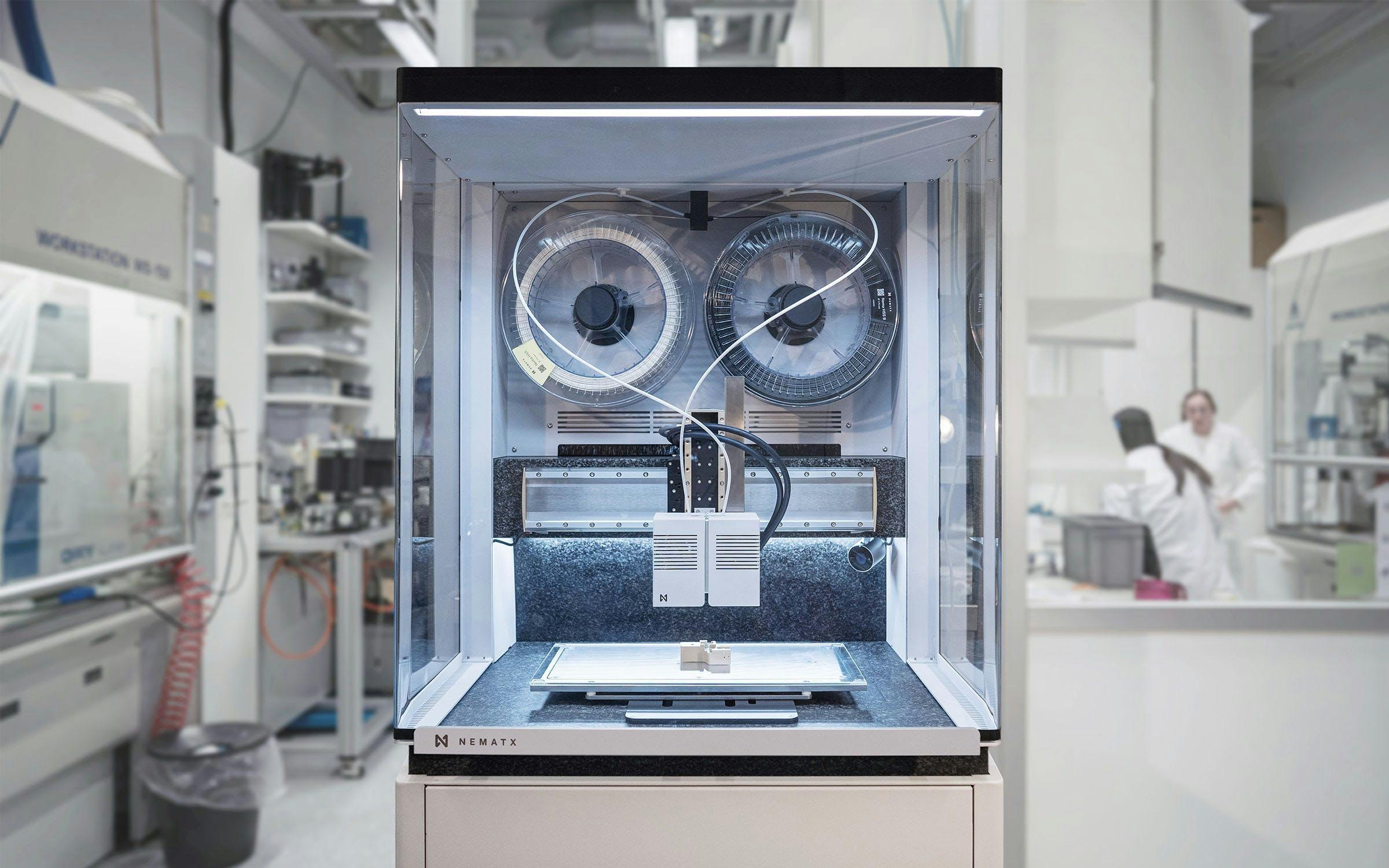

Designing for startups always poses a unique challenge, characterized by speed and a high degree of creative freedom. As an industrial design service provider, we took on the challenge of designing for NematX, a Swiss startup and spin-off of the prestigious Swiss Federal Institute of Technology ETH. Our team successfully managed the entire design project, from the initial concept to the launch of the NEX-01 industrial 3D printing platform at FORMNEXT 2022 in Frankfurt, within a tight timeframe of less than 6 months.

NematX features the "Nematic 3DP Technology", which was specially developed at ETH and is based on patented liquid crystal polymer (LCP) materials for additive manufacturing. In combination with proprietary part design algorithms and high-precision 3DP hardware, they offer the combination of part performance & manufacturing precision required for industrial production. The nematic 3D printing technology is based on material extrusion using Fused Filament Fabricaton (FFF) or Fused Depositon Modeling (FDM). During printing, they can align these individual packages LCPs along the print direction to produce parts with unmatched mechanical and thermal properties from polymer additive manufacturing. By controlling the molecular alignment of the LCP materials they achieve superior stiffness and strength from polymer 3D printing. In printing direction, they achieve Young's moduli of up to 25 GPa and ultimate tensile strengths of 650 MPa.

To achieve a print resolution of 25µm at a processing speed of up to 10m/s, NematX has mounted all linear guides on a precision honed granite block platform. This structure has proven to provide massive rigidity and vibration damping, as well as preventing dimensional changes due to temperature rise in the machine chassis, as demonstrated in measuring machines.

Design and function

Following the initial workshops, it was apparent to all project stakeholders that the machine should be distinct from competitors, who typically emulate the appearance of traditional CNC machines. The design mandate was to establish a unique formal language for an industrial 3DP platform. Additionally, the NematX team wanted to highlight their proprietary LCP material, as they aim to differentiate themselves as a material supplier.

It was evident to the FOND design team that the printer platform should embody precision, quality, and Swissness. We developed a formal vocabulary that blends a minimalist futurism with the classic principles of "Swiss Style," including conceptual strength, formal conciseness, and technical precision, updated for the 21st century. A circumferential waist, which runs directly onto the stone, subdivides the machine. In contrast to traditional 3D printers, we opted for a polycarbonate window that follows the edge details, providing maximum visibility into the production area. Due to the vertical opening, the production area is optimally accessible from three sides.

The formal design elements were inspired by Swiss Revox reel-to-reel recorders and early 1970s computers, using an angular and matter-of-fact design language that conjures up the ultra-clean and digital-looking laboratory-like manufacturing facilities of our post-industrial age. The result is a unique aesthetic for the NEX-01 that communicates precision, speed, and industrial ruggedness.

Usability and ergonomics

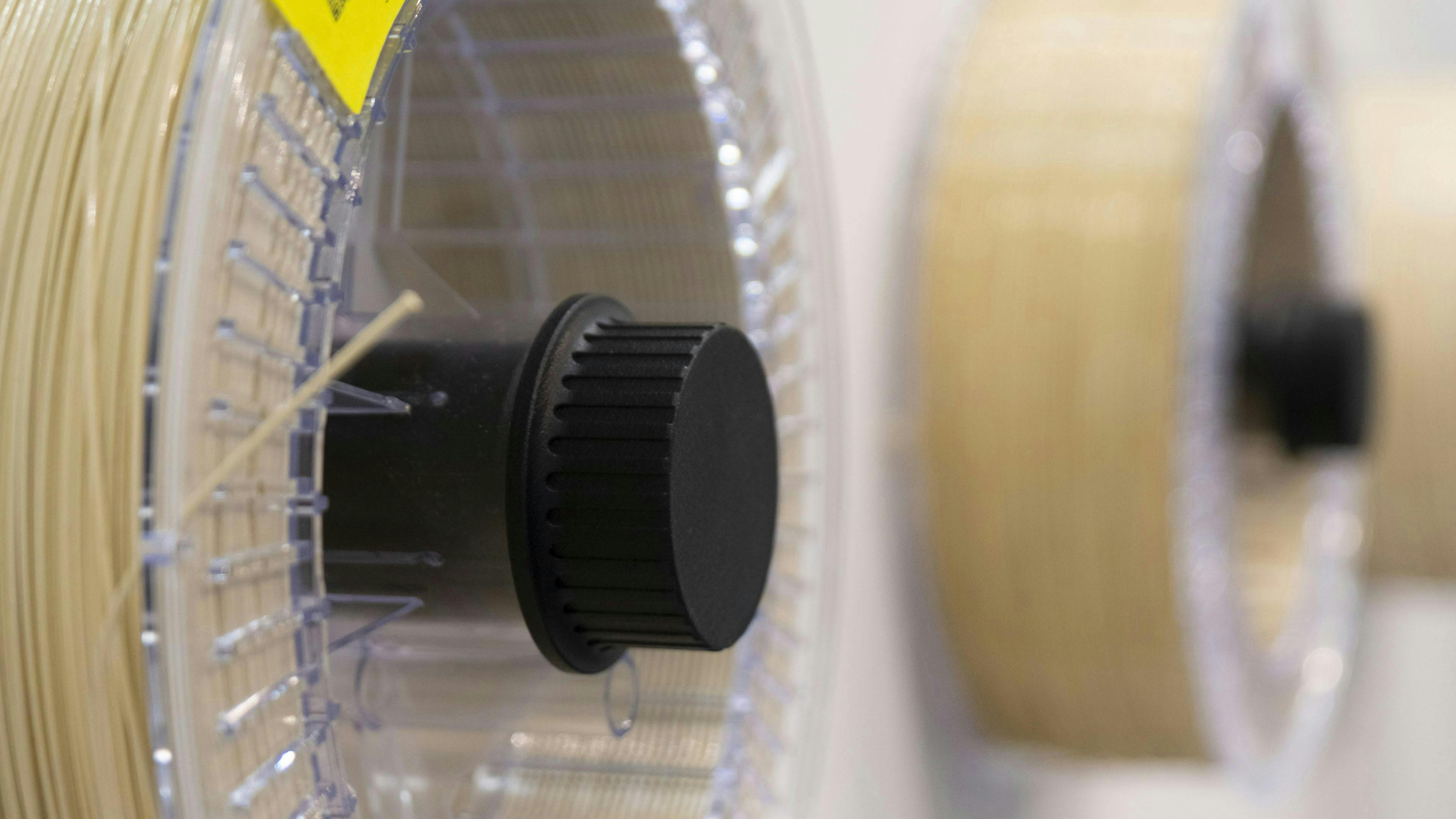

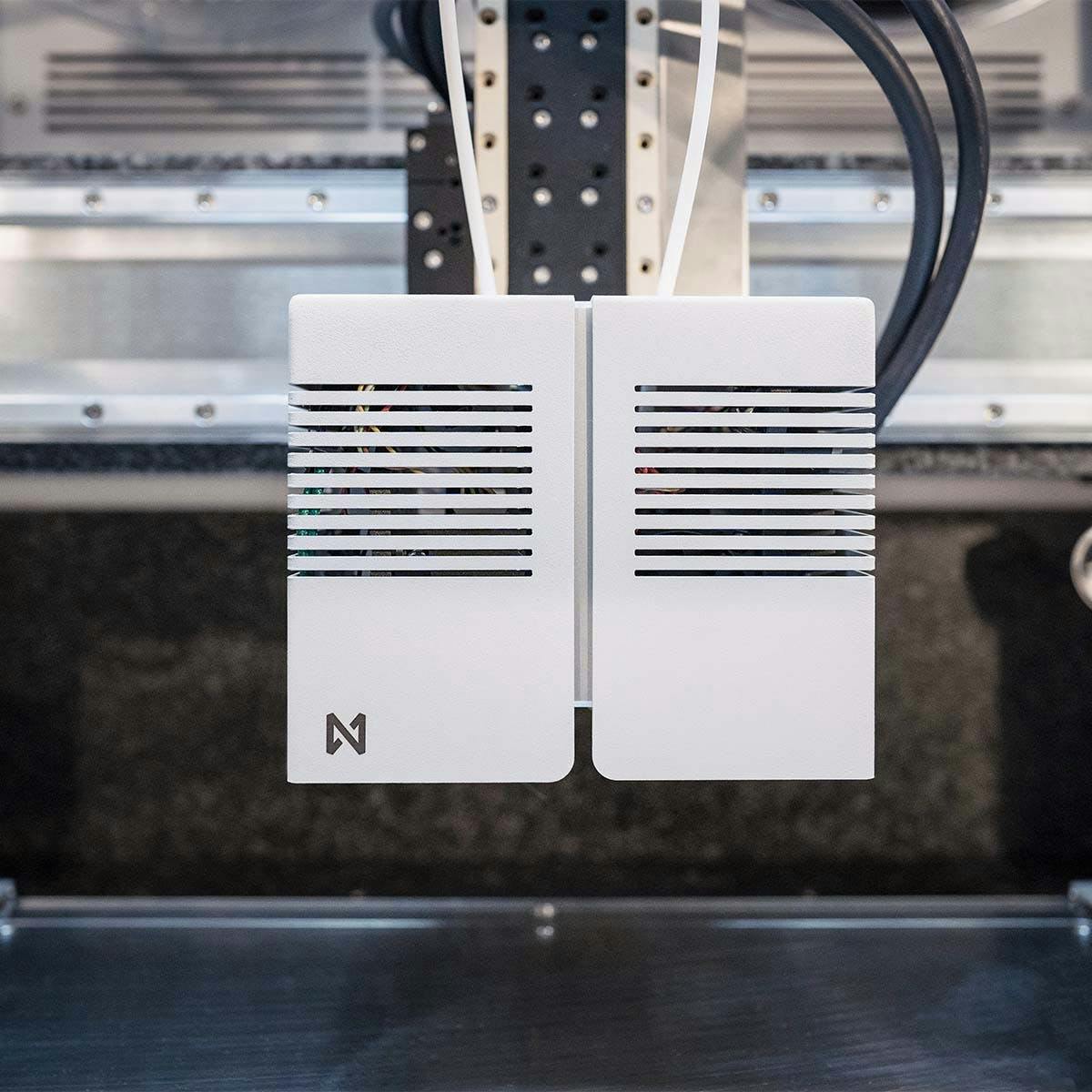

Our top priority throughout the design process was to ensure user-friendliness. We adjusted the work surface to the most optimal height, allowing for ergonomic operation, maintenance, and reloading of the machine. The filament rolls can be easily and safely replaced, thanks to the machine's good accessibility and large, ergonomically-shaped, multi-start locking screws. This is particularly important given the high filament consumption resulting from the machine's fast printing speed of up to four parallel print heads. Additionally, the central feeder mechanism ensures effortless infeed of new filaments. Working closely with the NematX team, we rigorously tested and optimized all aspects of usability through 1:1 functional mock-ups.

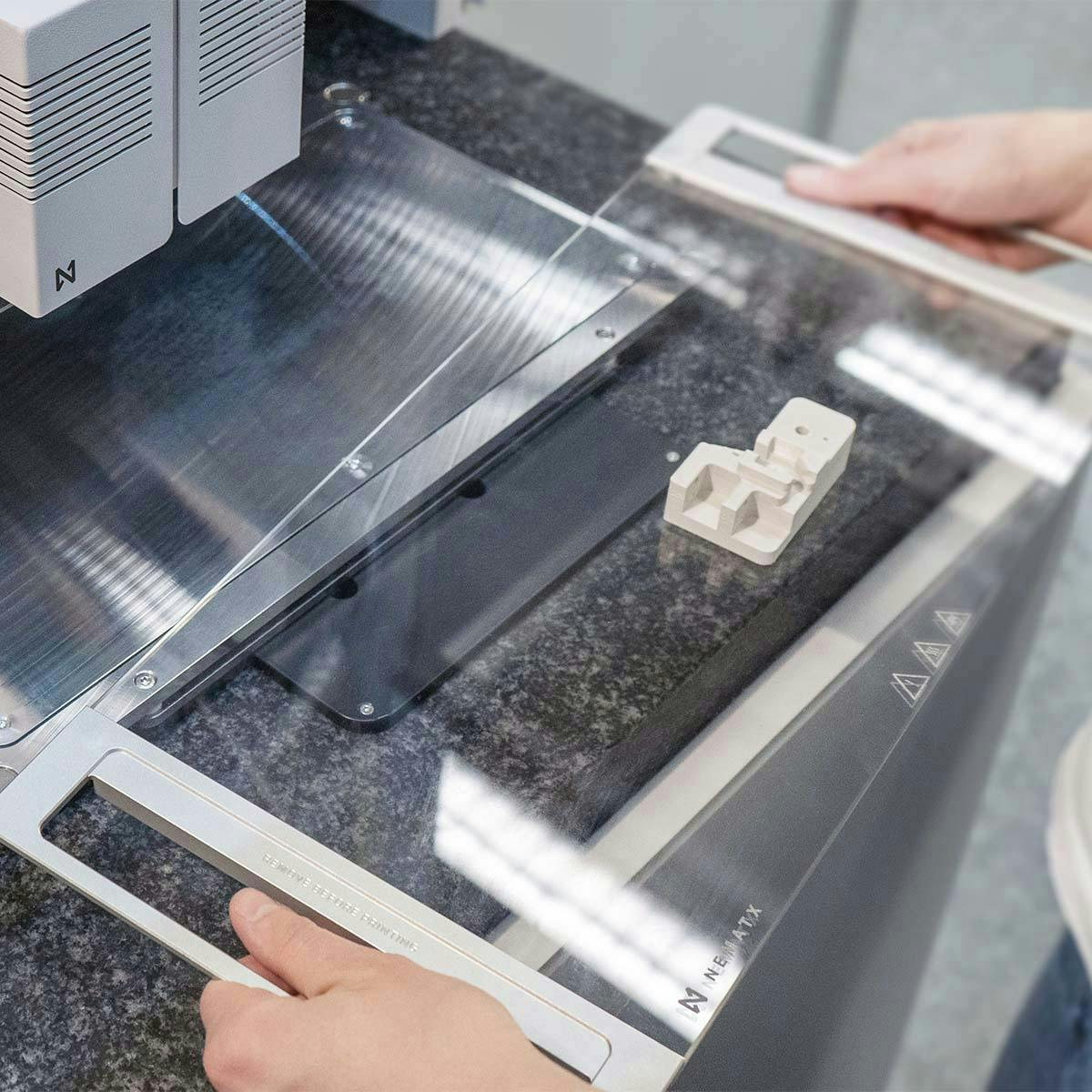

Our aim was to optimize the manufacturing process in terms of efficiency, safety, and usability. To achieve this, we developed a carrier system for the product using etched glass trays with detachable magnetic handles. The handles enable easy and secure stacking of the trays, conserving space. During the manufacturing process, the glass plate is heated to 150°C (300°F), so the aluminum handles need to be quickly detached. After printing is complete, the handles are reattached to allow safe handling of the hot tray containing the finished products.

Market introduction and communication

To maximize the limited time between the initial design and the presentation of the new machine at Formnext in Frankfurt, we provided NematX with visual aids and animations for effective communication. This allowed NematX to engage with potential customers and stakeholders through various channels even before the machine was ready. Additionally, we refined NematX's original corporate design to establish a cohesive and compelling brand image. For the trade show exhibit, we crafted a sleek and minimalist booth that effectively conveyed NematX's strengths and values: Swiss-made industrial precision tailored for 3DP.

The response from the professional community towards the 3DP platform has been overwhelmingly positive. Both the independent design of the NEX-01 and the impressive appearance of the new market entrant, NematX, have garnered international recognition and piqued the interest of investors, specialized manufacturers, and customers seeking customized parts. Our team is immensely proud of this project as it exemplifies how strategic and meticulous industrial design can provide a significant edge to a new player in the market. Moreover, the machine and its usability have withstood thorough scrutiny from industry experts, particularly due to the user-focused details and ergonomic considerations incorporated into the design.